spieth10@spiethstorage.com

spieth10@spiethstorage.com +8615259233328

+8615259233328

-

Tel : +8615259233328

Tel : +8615259233328

-

E-mail : spieth10@spiethstorage.com

E-mail : spieth10@spiethstorage.com

-

Address : Tongan Park, Tongan District, Xiamen, China 361023

Address : Tongan Park, Tongan District, Xiamen, China 361023

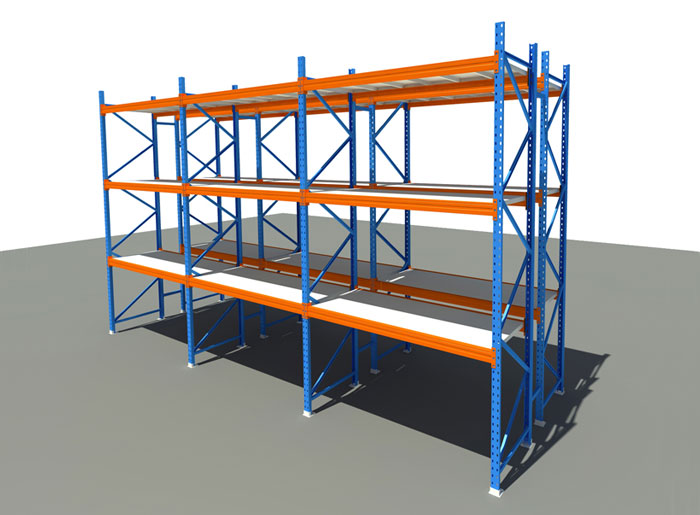

Warehouse Storage Selective Pallet Racking

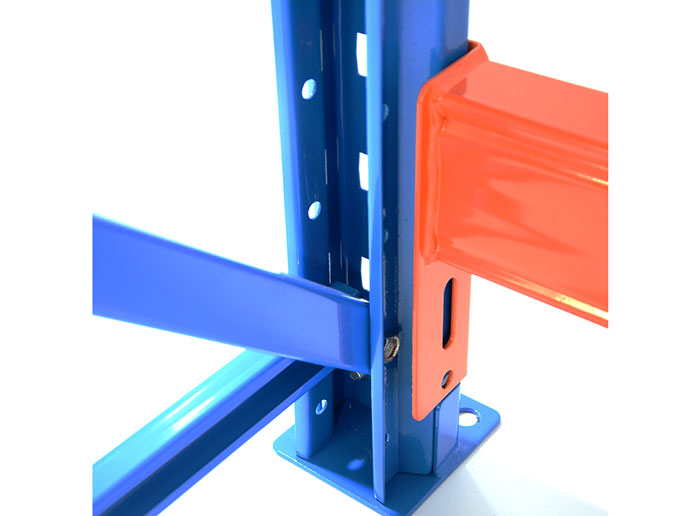

Roll-formed pallet racks are the most popular, functional warehouse racking in the industry. As the best solution for warehouse systems with palletized products, they store a wide variety of goods. The selective pallet rack is the main component of every warehouse storage system.

Selective pallet racks, also commonly known as beam pallet racks, or pallet storage racks, are usually heavy-duty warehouse storage racks and are the most common in various storage pallet rack design layout systems. The pallet rack system has high space utilization, flexible and convenient access, supplemented by computer management or control, and can basically meet the requirements of modern logistics systems pallet rack warehouse & supply.

The shelf span of the selective pallet racking is generally less than 4m, the depth is less than 1.5m, the height of the low and high warehouse storage pallet racks is generally less than 12m, and the height of the ultra-high warehouse pallet rack is generally less than 30m (such warehouses are basically automated warehouses, and the total height of the warehouse storage racks is It consists of several sections of uprights within 12m). In such rack warehouses, most of the low-level and high-level warehouses use reach battery forklifts, counterbalanced battery forklifts, and three-way forklifts for access operations. Electric stackers can also be used when the warehouse storage racks are low, and stackers are used for ultra-high-level warehouses.

The pallet rack manufacturer can be configured pallet rack shelving for various uses and product sizes. One option is double deep pallet racking, which increases storage capacity by enabling four pallets to be stacked back-to-back (requires a deep truck). The heavy duty pallet rack can also be used to construct rack-supported buildings, as well as for more basic storage needs in any warehouse installation. Combine them with hand-stacking racks for the best results.

Advantages of Pallet Rack

- Direct access to each pallet.

- Simple inventory management.

- Cost savings with long-span beams.

- Suitable for any product volume, weight, or size.

Applications of Pallet Rack

Selective pallet racks are widely used in manufacturing, third-party logistics and distribution centers, and other fields. Pallet racks are most used in high-level warehouses and ultra-high-level warehouses and are divided into drive-in pallet racks and gravity pallet racks.

Packing and Shipping of Pallet Rack

-

Do you offer samples available?Yes, samples are available. Sample lead time 3-5days generally.

-

Do you offer custom design?Custom design is surely available. we have very rich experience in customizing shelves.

-

What is the term of payment?Regularly, 30percentTT in advance,70percent against the copy of B/L.

-

What is your delivery time?Usually: 1*20' GP container, around 15 days; 1*40'GP container, around 20days; For some urgent orders,will adjust as your requirement accordingly.

-

Are you manufacturer or trading company?We are manufacturer. Our factory has been specializing in warehouse storage equipments for years. We warmly welcome you to visit our factory at anytime.

-

-

+8615259233328

+8615259233328

0

0

Link:

Link: