spieth10@spiethstorage.com

spieth10@spiethstorage.com +8615259233328

+8615259233328

-

Tel : +8615259233328

Tel : +8615259233328

-

E-mail : spieth10@spiethstorage.com

E-mail : spieth10@spiethstorage.com

-

Address : Tongan Park, Tongan District, Xiamen, China 361023

Address : Tongan Park, Tongan District, Xiamen, China 361023

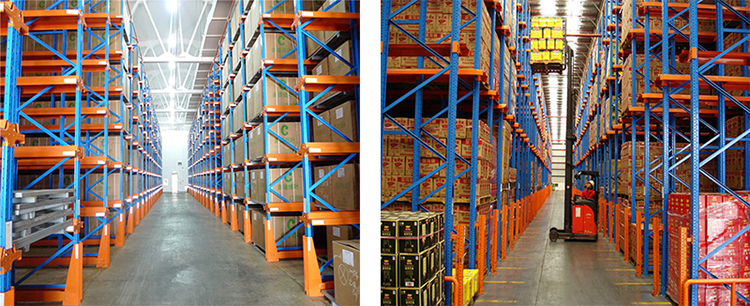

Industrial Warehouse Drive-in Pallet Storage Racking System

Drive-in racking is a high-density pallet storage system where the outer sides of the pallet are supported on rails. The rails create a lane and the length of the rails determine how many pallets deep the system will be (typically 2 - 10 pallets).

Drive In Pallet Racking Description:

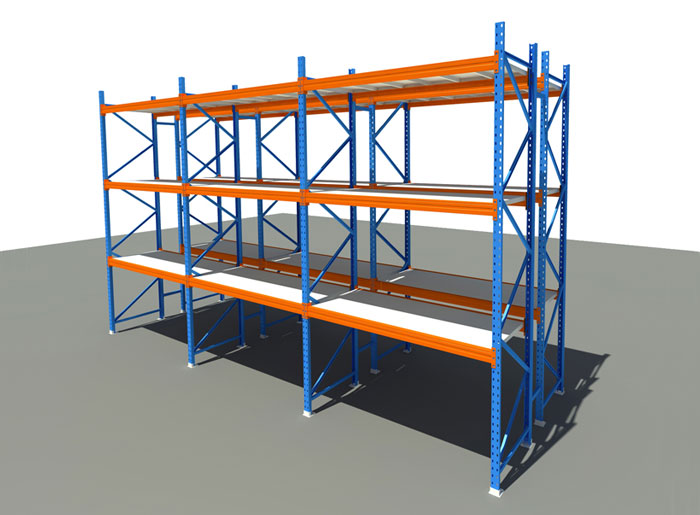

Spieth drive in pallet racks are a cost-effective solution to high-density storage. This static system has rails running the depth of the rack for pallet placement. The only limitation to the depth of pallet storage is the capability to drive deep within the system. The rack depth reduces the need for aisles and drastically increases cubed space utilization.

Drive-in racking is a high-density pallet storage system where the outer sides of the pallet are supported on rails. The rails create a lane and the length of the rails determine how many pallets deep the system will be (typically 2 - 10 pallets). The forklift aisle runs perpendicular to the drive-in lanes and a single aisle can service many lanes on either side, providing a very high pallet position-to-aisle ratio. The operator drives into the required lane to store and retrieve pallets

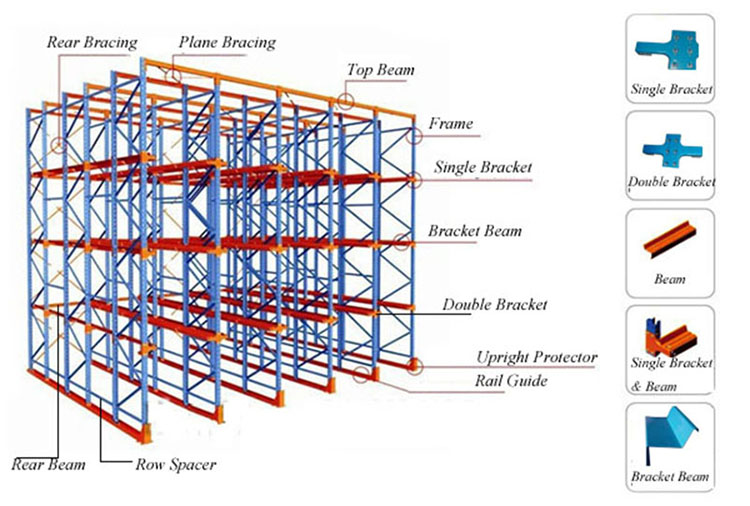

Drive In Pallet Racking Details:

Features:

1. Drive-In Drive-Through systems provides maximum storage capacity using the minmum amount of the space

2. It is particularly suited to store very large quantities of homogeneous products.

3. Drive-In Drive-Through systems racks operate on the basic First-In Last-Out.

4. Compatible with many handling equipment styles.

5.The height between levels can be adjusted easily by 75mm assemble quickly and easily with a hammer or mallet. Widely used in cold room warehouse.

6.Shelves can be adjusted per 75mm pitch.

7.Corrosion resistant: tough power coat finish resists rust and cratches.

8.each shelves holds up to 1000-4500kg.

9.Sturdy industrial strength steel construction.

Packing&Shipping

-

Do you offer samples available?Yes, samples are available. Sample lead time 3-5days generally.

-

Do you offer custom design?Custom design is surely available. we have very rich experience in customizing shelves.

-

What is the term of payment?Regularly, 30percentTT in advance,70percent against the copy of B/L.

-

What is your delivery time?Usually: 1*20' GP container, around 15 days; 1*40'GP container, around 20days; For some urgent orders,will adjust as your requirement accordingly.

-

Are you manufacturer or trading company?We are manufacturer. Our factory has been specializing in warehouse storage equipments for years. We warmly welcome you to visit our factory at anytime.

-

-

+8615259233328

+8615259233328

0

0

Link:

Link: